Grinding

Milling and and size reduction.

The economic and efficient preparation of raw materials for

further processing improves the production results and ensure quality.

Acmon Systems provides solution for breaking lump mill as well as fine

powder mill to choose the right alternative. In order to achieve cost

effective, highly eficient solution for coarse and fine size reduction,

granulation and also the de-agglomeration of lumps we collaborate with

German specialized company JEHMLICH

1) Pre-Crusing

A) Hammer Mills

Material Examples

gypsam, LCD displays, rock salt, bones,

plastic composites, circuit boards, foundry sand,

fibre cement, glass granulate, wood, electronic scrap,

fertilizers, horn, sewage sludge, brake pads

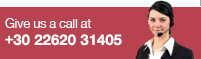

B) Lump Breakerplastic composites, circuit boards, foundry sand,

fibre cement, glass granulate, wood, electronic scrap,

fertilizers, horn, sewage sludge, brake pads

Material Examples

sinter cake, bakery rework, proteins, starch, ash

magnesium chloride, confectionery, foundry sand,

iron hydroxide, extrudates, lactose, urea, filter dust,

cilicon carbide, carbon clack, pvc-agglomerates,

fertilizers, sewage sludge, sugar, citric acid

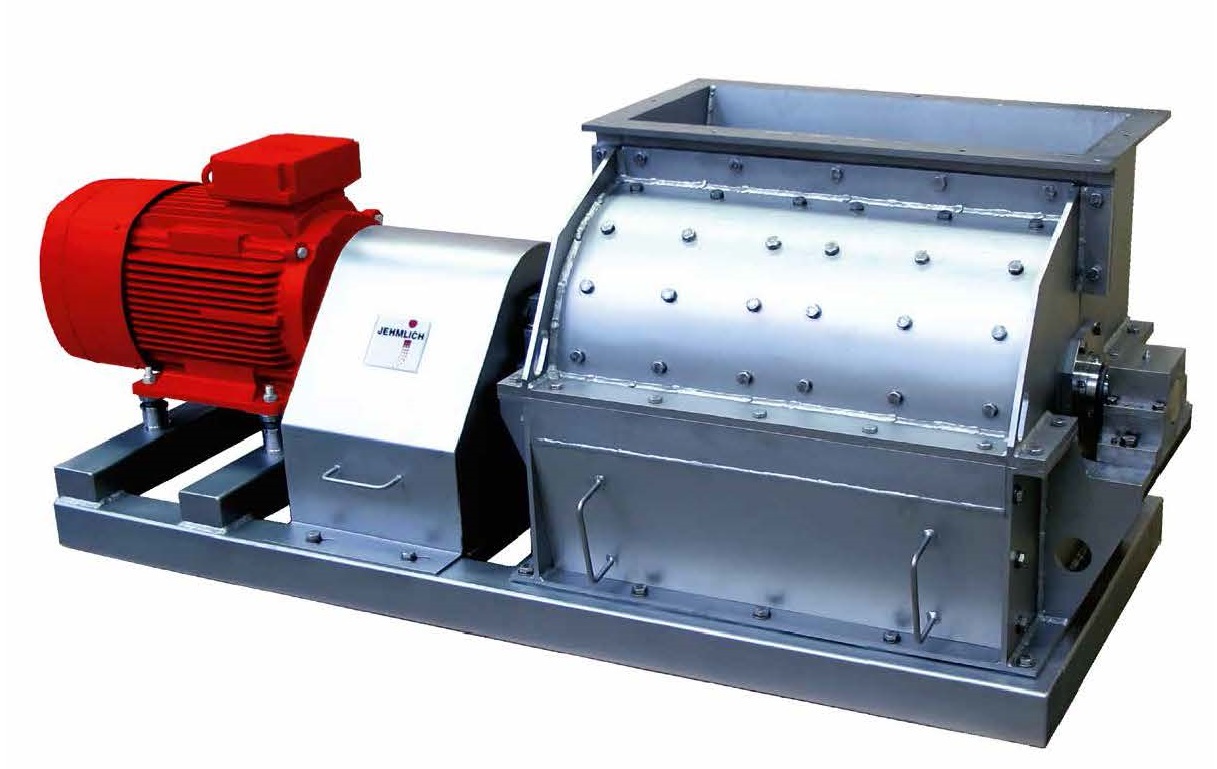

2) Impact Mills

Material Examples

gypsam, iron hydroxide, cell culture feed, carbon black,

tungsten carbide, glass granules, cellulose, lupine protein,

sugar, fibre cement, hemp prpotein, graphite, coal,

copper oxychloride, fat-sugar-mixtures, coffee, plastics,

dried vegetables, food phosphates, salts, pepper,

cocoa, pigments

3) Grinding Plants

We offer you project planning, design, manufacturing, and realization of complete and extensive crusing solutions (turnkey), including in-house switch cabinet construction, world-wide installation and commisionning

We do believe that the best way to justify the quality and the high level of the technical solutions of ACMON System's products is through our "live" projects.

We do believe that the best way to justify the quality and the high level of the technical solutions of ACMON System's products is through our "live" projects.