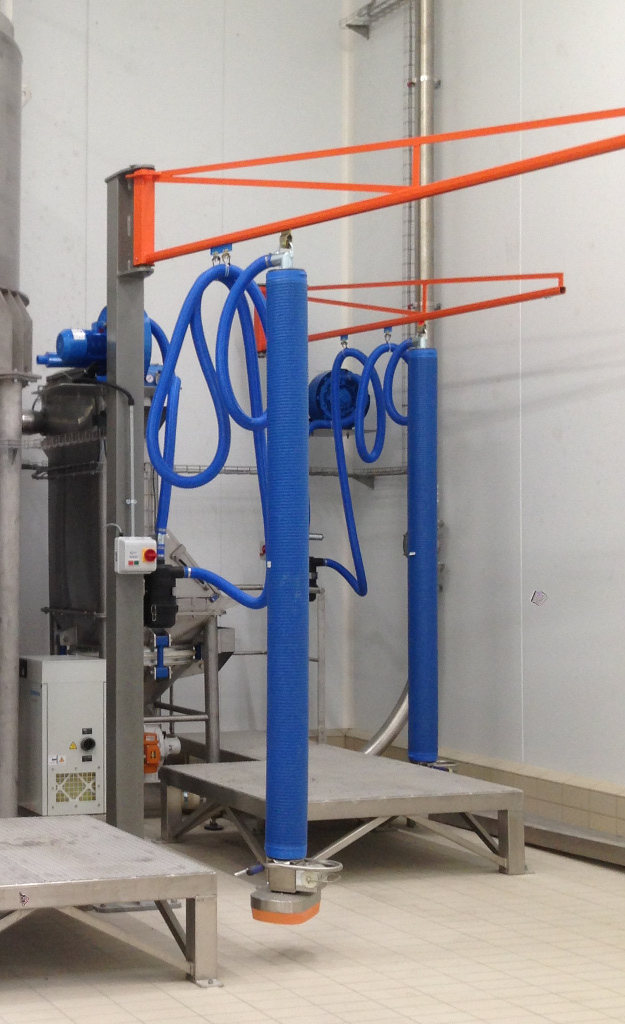

Bulk material feeding system for ice cream and yogurt pasteurization assemblies

Delivered in full operation for a known dairy production company, a bulk material feeding system for ice cream and yogurt pasteurization assemblies.The system includesι:

- Sack splitters with sieve and magnet for bulk materials impurities retention during the reception from sacks.

- Silo pneumatic filling system

- Internal daily storage silos

- pneumatic feeding system of weighing station

- weighing feeding station

- Central ventilation system

- Scada - dynamic imaging system and remote processes control.

|

The design and manufacturing took into consideration and complied with the specific requirements for:

- ATEX study for the zone identification and equipment characteristics to be compatible with ATEX zones

- Equipment in stainless steel construction in AISI 304

- Central ventillation installation for complete dedusting of equipment and surrounding area.

- Use of vibrating sieves and magnets for extraction of foreign materials.

- Fast and easy cleaning - maintenance

- Hygienic type machinery

- Special sack Lifters for fast and effortless lifting of sacks to be split

Sack Splitters |

Design in 3D |

Sack Lifters |

See also at Projects Overview:

Cement board panel production plant (Aquapanel) |

Project for packaging Semolina/Flour |

Turn key project for Pasta Production |

Bleaching powder production plant |

Production of WPC (Wood-Plastic Composite) |

Materials receive, dosing and feeding mixers |

Production - mixing of special thick colored plaster |

Bulk material feeding system for ice cream and yogurt pasteurization assemblies |

Admixture Plants in BPV Industry |

An integrated turn-key premix material factory for Bakery & Confectionary market

We do believe that the best way to justify the quality and the high level of the technical solutions of ACMON System's products is through our "live" projects.

We do believe that the best way to justify the quality and the high level of the technical solutions of ACMON System's products is through our "live" projects.